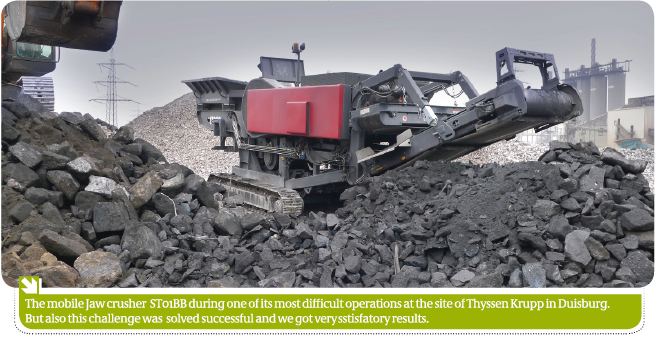

After our successful operation in Czech Republic the hydraulic jaw crusher was transported to the next mission at the site of Thyssen Krupp MillService & Systems (www.tkmss.com) in Duisburg. A company of the Thyssen Group which assigned us to do a trial operation. After the arrival at the company site in Duisburg, we lost our calmness promptly when we saw the material which was prepared for the trial operation. The material was worse than any material we have seen before. It would have been better described as steel with slag inclosures.

The operation began on February, 11th at the site in Duisburg.

Regarding the german precision we would like to state that we have never before executed an operation which was planned and organised as professional as this one. Before we started the work we received an operation schedule with information about the requirements and the processing materials for the whole week from the project manager, Mr. DI Daniel Borttscheller.

The material processed on Monday and Tuesday did not cause any problems for our crusher. However it showed that there could also be iron beams in pre-sorted materials, which would cause serious damages or shutdowns when processed with an usual crushing plant.

Every 20 – 30 minutes we had iron beams with edge lengths up to 300 mm which have been missed during the pre-sorting. Our crusher was unimpressed by the inlays and did a great job with this difficult materials.

The both screen curves show the final materials with a gap-adjustment of 70 mm (content of 0/63 mm of 73,4%)and with a gap-adjustment of 50 mm (content of 0/63 mm of 98,7%). All in all we have been processing 540 m³ of this material.

Much more difficult was the crushing of the prepared furnace lining. With an edge length of 900 mm the stones were too big for an impact crusher and with a conventional jaw crusher this material would slide off through the graphite content. This means that the material would slip off in the crushing chamber similar to a wet soap in your hands.

After we found the right setting for the crusher we were able to process the material without further problems.

In total we have processed 550 m³ of furnace lining. A big advantage has been the special movement of our crusher (much more aggressive at the entry area) and the large gap-setting from 20 to 250 mm without any change of the kinematics.

But the materials of the first 3 days were nothing compared with the ones which we had to crush from Thursday on. Every bucket of the excavator was a challenge. The crusher itself was unimpressed by the material, but the rest of the plant reached the limit.

Between the bottom edge of the crusher outlet and the main discharge conveyor there is a distance of 800 mm which is more than enough for usual applications. But if the material contains heavy iron beams with a length of 800 mm and a gauge of 300 mm unfortunately this distance is not enough.

Furthermore the mounted permanent magnetic separator reached its limits several times. The iron beams have been so massive that their contact pressure caused a blockage of the discharge conveyor.

All in all we have processed 70 m³ of this material and were able to prove the functionality and endurance of the crusher. However for a permanent operation with such a material we would recommend a stationary solution of our crushing unit under consider-ation of the discharge heights and magnetic technology.

In total we have been processing 1.180 m³ of material during this trial operation. With a bulk density of 2,5 t/m³ this means about 2.950 tons, and with a total of 24 operation hours this results in an hourly performance of 125 tons.

Currently our demonstration plant is in the way to the next operation in Hamburg and afterwards we are again operating for Thyssen Krupp MillServices&Systems, this time at site in Brandenburg.