As already reported in our last issue of our newsletter, our mobile Jaw crusher and our mobile magnetic separator have been in trial operation at a slag landfill in Czech Republic.

The first results of the trial operation will be presented in this new issue.

The slag landfill exists since the founding of the closely located steelwork in 1889. It has an area of 44 hectares and due to the sheer size, the material dumped is very diverse. On a continuous basis, material is found that either cannot be processed at all by the existing stationary plant or would at least result in enormous costs and pre-sorting efforts. Therefore a treatment of tis quality of material is at the moment not possible in an economic sound manner. But especially this material contains valuable iron and metal parts, which should be recycled, due to its high profitability.

During our first trials we particularly wanted to clarify the maximum possible sizes of feeding material and what final material could be produced with which performance. These specifications are the base for a first calculation to compare the costs with the costs for conventional treatment using excavators, hydraulic-hammers, magnetic plates and hand-sorting.

During our first trials we particularly wanted to clarify the maximum possible sizes of feeding material and what final material could be produced with which performance. These specifications are the base for a first calculation to compare the costs with the costs for conventional treatment using excavators, hydraulic-hammers, magnetic plates and hand-sorting.

The existing stationary plant can process material with an edge length of up to 300 mm. Bigger parts have to be sorted out using pre-separator grids and excavators. Free iron beams are withdrawn and exploited. However, the slag itself is deposited again, due to the high costs for recycling. But exactly this slag would be valuable for recycling as it contains about 15 % of iron and metal parts. This results in an equivalent value – according to the present scrap-price – of EUR 20 – 30 per ton.

In order to process this material with conventional technology, the use of a multi level crushing process in small steps would be indispensable. The iron and metal parts would lead to a shutdown and cause major damages in case of adjusting a small gap.

Even hydraulically guarded jaw crushers, as they are already in use for construction waste recycling, can currently not crush this material on a long term basis in an economic manner. The occurring forces are too strong, after some weeks of use the crusher is worn out.

In comparison to conventional hydraulically guarded jaw crushers the occuring strength in the ST01BB is not fed 100 % into the hydraulic cylinders. Because of our deviating mechanism about 80 % of the occuring forces stay within the very strong chassis of the jaw crusher and only approximately 20 % have to be absorbed by the hydraulic cylinders.

According to the pre-set pressure which can be adjusted between 30 and 60 bar (level depends on the type and size of the feeding material) the crusher chamber opens independently as soon as non-crushable extraneous materials are in the chamber and is closing to the pre-set position within seconds when those materials are

leaving the chamber.

We have been able to reach an average performance of 80 m3/h in processing blast furnace and LD-slag with a feeding size of up to 900 mm and a gap adjustment of 60 mm. This means in turn an hourly performance of 256 tons when converting this heavy material with a bulk density of 3.2 t/m3. The stated quantity has been measured through the volume measurung system mounted on the main conveyor.

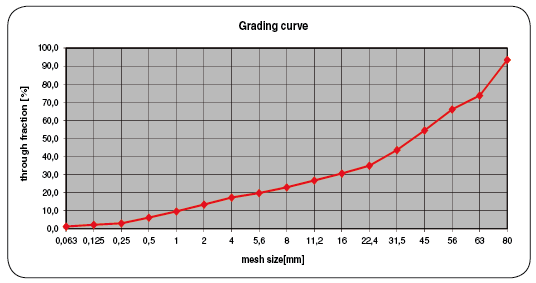

73,7 % of the material was smaller than 63 mm after the one-time crushing process.The oversize material

only occured when the crusher was opening the chamber because of non-crushable materials. Further second level crushing trials have shown that the oversize material also could be crushed 100 % into a final grain of 0/63 mm after the elimination of the iron parts.

With our hydraulically guarded jaw crusher it is possible to produce a final grain of 0/63 mm of problematic materials up to an edge length of 900 mm without any additional crushing of the material. The further preparation of slag with a grain size of up to 63 mm can be processed with conventional crushing equipment.

The subsequent trials with our mobile magnetic separator will give more details about how much iron/metal could be obtained from the material.

Download Newsletter Issue 3, high resolution. (PDF, 1,1MB)

Download Newsletter Issue 3, low resolution. (PDF, 420kB)